Researchers at the University of Michigan set out to create a battery technology that would prevent the sort of battery fires recently seen in the new Boeing 787 Dreamliner. As is often the case with breakthroughs in technology, their findings have the ability to solve more than their intended goals. In this case, thinner lighter batteries could potentially be used to make nearly any other tech better. Think of thinner cell phones with the same juice you’re seeing now, or even the same size phones with even more juice thanks to this research.

We’d all love to have an awesome phone with a battery that lasts for three weeks but current battery technology simply can’t hold up to those standards. I’m not saying that you’ll get anything close to that outrageous estimate once these batteries go into production, but it’s possible to see improvement simply from more mAh getting dragged out of similarly-sized batteries. The researchers at the university are so confident in this breakthrough that they’ve already founded a company – Elegus Technologies – to ultimately bring this discovery to market.

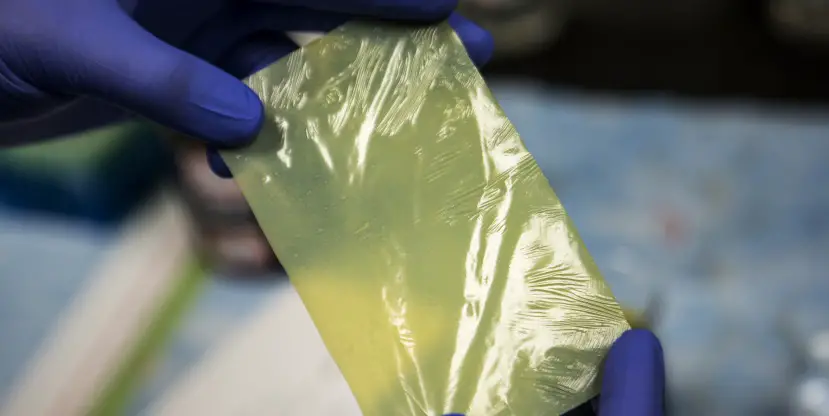

The secret weapon in the fight is Kevlar. You’ll likely recognize the material from bulletproof vests, but I wouldn’t recommend shooting these batteries as they simply incorporate Kevlar nanofibers to act as a barrier between the electrodes in a standard lithium-ion battery. I’ll leave the super-sciencey description of why this is important to the researchers:

Lithium-ion batteries work by shuttling lithium ions from one electrode to the other. This creates a charge imbalance, and since electrons can’t go through the membrane between the electrodes, they go through a circuit instead and do something useful on the way.

But if the holes in the membrane are too big, the lithium atoms can build themselves into fern-like structures, called dendrites, which eventually poke through the membrane. If they reach the other electrode, the electrons have a path within the battery, shorting out the circuit. This is how the battery fires on the Boeing 787 are thought to have started.

Batteries shorting out is bad… So how does Kevlar help?

“The fern shape is particularly difficult to stop because of its nanoscale tip,” said Siu On Tung, a graduate student in Kotov’s lab, as well as chief technology officer at Elegus. “It was very important that the fibers formed smaller pores than the tip size.”

While the widths of pores in other membranes are a few hundred nanometers, or a few hundred-thousandths of a centimeter, the pores in the membrane developed at U-M are 15-to-20 nanometers across. They are large enough to let individual lithium ions pass, but small enough to block the 20-to-50-nanometer tips of the fern-structures.

The real good news though, comes from this quote right here:

“The special feature of this material is we can make it very thin, so we can get more energy into the same battery cell size, or we can shrink the cell size,” said Dan VanderLey, an engineer who helped found Elegus through U-M’s Master of Entrepreneurship program. “We’ve seen a lot of interest from people looking to make thinner products.”

Thinner products indeed. They’ve already received significant interest in their new Kevlar film, with thirty companies asking for samples as of 1/27. There’s no word on when we might start seeing this new technology roll out to consumer products, but anything that can help us get more power out of our devices should be worth the wait.

You can read more about this discovery at the source link below.

[button link=”http://ns.umich.edu/new/multimedia/slideshows/22645-bulletproof-battery-kevlar-membrane-for-safer-thinner-lithium-rechargeables” icon=”fa-external-link” side=”left” target=”blank” color=”285b5e” textcolor=”ffffff”]Source: University of Michigan[/button]Last Updated on November 27, 2018.

Comments are closed.