Automation has been prevalent in the automotive industry for decades now. The industry has been among the first to adopt new and advanced machinery and tools. Still, a big percentage of hardware used has been limited compared to some of the technologies in the market today.

About Traditional Robots

Traditional robots are ideal for one or multiple tasks. Each unit passes through a production line where different robotics is used at each position. Traditional robots are not as efficient as automotive robots.

New Technologies

Technology has been advancing at a rapid rate. Today, new solutions such as cloud computing, IIoT (Industrial Internet of Things), and 3D computing have revolutionized the manufacturing sector. The adoption of these technologies will transform the industry, making it fully automated.

Some of these technologies have brought about the introduction of new strategies. For instance, 3D printing makes way for in-house, almost instant evolution of parts. As automation evolves, there are some trends to watch out for as we shall see below.

The Rising use of Cobots

A big percentage of automotive development and manufacturing is automated but human input is still required. Traditionally, robots were used for dangerous and repetitive tasks that human workers should not execute. However, following advancements today automotive robots can jointly work besides human workers.

These advanced units are referred to as cobots or collaborative robots. Many vehicle manufacturing companies depend on cobots to ensure workers in their plants are safe. Automotive robots also come in handy to guarantee the production of good quality goods and parts.

3D Printing Accelerates Operations

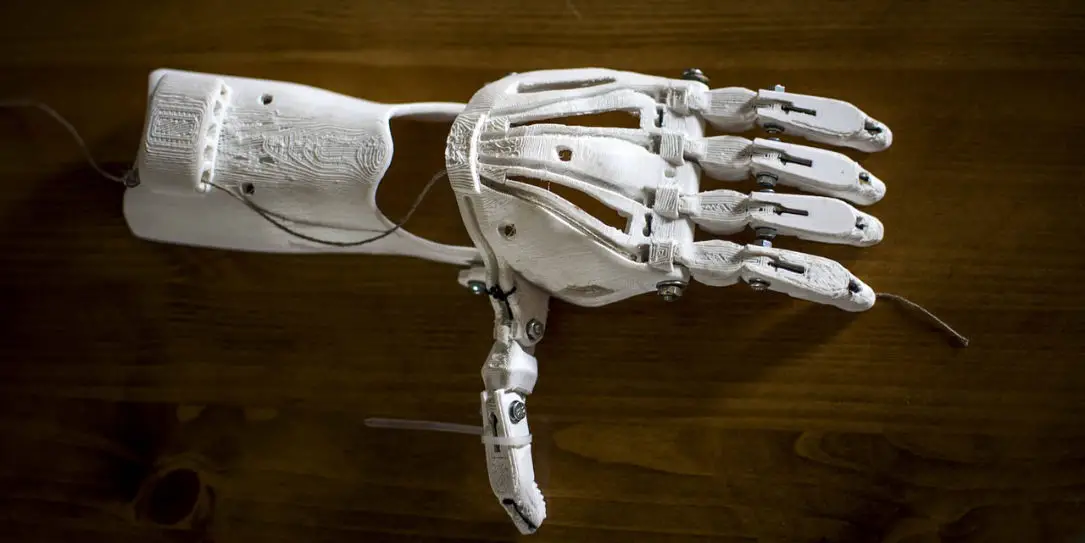

3D printing is also known as additive manufacturing. This technology is fast becoming popular in the automotive sector. What was in the past entrusted to small projects and enthusiasts has now been advanced to develop larger parts ideal for multiple forms of manufacturing. 3D technology is today used to print with different new materials ranging from wood, masonry, and concrete.

3D printing is designed to develop items tier by tier from the base up. Its composition will have a big impact on vehicle assembly. Advanced welding functions such as radiofrequency welding (RF) are usually used to combine parts more permanently.

Welding is a necessary process but 3D printing reduces its significance in intricate builds. What this means is that while the resulting parts are strong, they are produced within a short time and can be assembled faster too.

It is no wonder that the automotive sector is leveraging the potential of this technology to help create different parts for modern cars. This has been happening since 2015 according to reports. The report suggested that motor vehicles comprised 16.1% of the additive manufacturing market in that year.

The number has since grown tremendously. Various vehicle manufacturing companies now use 3D techniques to print spare parts and metal prototypes for their cars. As technology advances, becomes more readily available, and cost-effective, more vehicle manufacturing companies will include it in their daily manufacturing processes.

Emergence of Vehicle Autonomy

While automation is evolving constantly for customers, vehicles are achieving autonomy. Fully autonomous and self-driving vehicles are expected to be in the market in the near future. Some estimation suggests that up to 15% of cars sold in 2030 will be entirely autonomous. It’s worth noting that technology needs to be improved and perfected before all this happens.

Regulation will also be necessary from the user operation, insurance, and legal standpoint. Electric vehicles are becoming more popular as players move collectively towards more environmentally sound and efficient solutions.

With continued evolution, these technologies become more viable, capable, and cost-effective. Reports indicate that by 2030 electrical vehicle shares may range between 10 and 50% of all new vehicle sales. Adoption rates will be higher in the dense and urban areas. Cities often have stricter emission regulations and more consumer motivation to go green.

The Automotive Industry is Evolving Constantly

Automation has been part of the manufacturing and automotive industries for a long time. Many automotive manufacturers leverage advanced technologies to execute repetitive and dangerous tasks. Adopt automotive robots in your organization today and enjoy enhanced productivity.

What do you think of these trends in the automotive industry? What trends are you seeing that we should know about? Let us know in the comments below or on Twitter, or Facebook. You can also comment on our MeWe page by joining the MeWe social network.

Last Updated on February 3, 2021.