Constructing electronic devices and hardware is like putting together a complex puzzle. They are built up of several critical components that must be masterfully crafted together to create a complete unit that uses each part. This is a big reason why the design phase of a product’s development cycle is of utmost importance.

With the development of the economy and the progress of science and technology, electronic products are popularized in the people’s production and life, bringing great convenience to the people’s production and life. Electronic products’ popularity has made people use the way of letters to become more convenient ways of communication through mobile phone, telephone, or even Internet chat software.

The Real Impact of Product Design

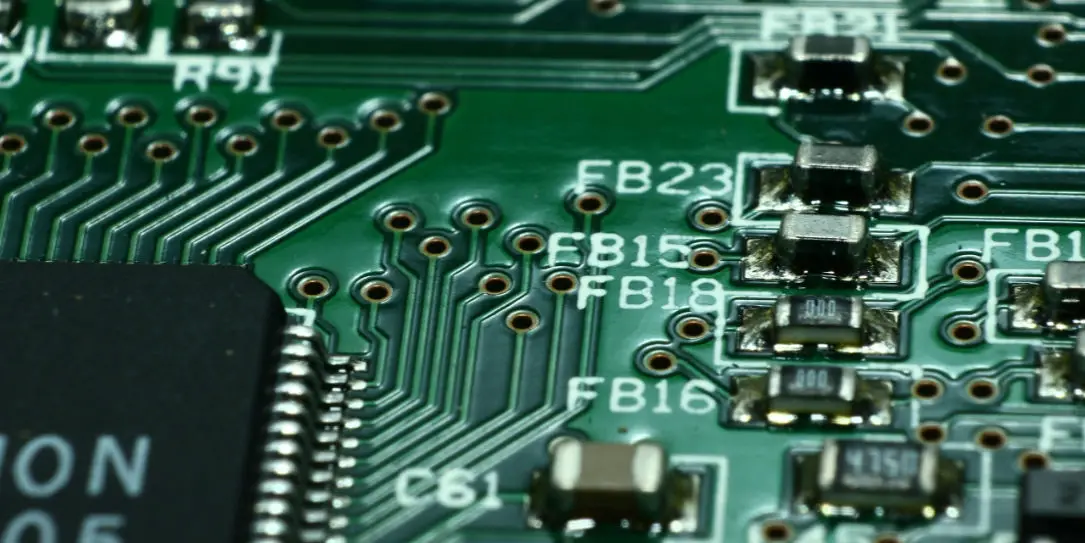

When goods enter production, schematics are thoroughly examined in order sure components are going to be functional. Hardware is constructed in a manner that fulfills the goals the end product is trying to reach. Throughout a development process, various processors, motherboards, and more are innovated upon and improved to ensure that each part is placed at a point at which it can well interact with another required component. The board is the foundation of the entire product and what components need to be built around and considered.

This is why design is critical to every step of a product life cycle because it can impact how successful a product is once it gets out of the gate. Products in almost every industry face fierce competition, and there are often several different ways they can be constructed. Take a phone, for example. Even though they look similar, you can always tell whether you’re looking at an iPhone than another smartphone brand.

Naturally, most businesses invest heavily in the design phase; for example, custom electronic design services help businesses develop designs and schematics for products that will eventually hit the market. Design solutions are quite lucrative because a well-designed product will naturally have a leg up on the competition, which every business will want their products to achieve.

Modeling and design tools are developed to aid the machine design and drive development efforts. Particular research emphasis is on permanent magnet and reluctance type machines and drives.

What Makes a Strong Design

Some key considerations to keep in mind for a successful design are keeping it functional and well-performing while maintaining something unique that sets it apart from the competition. To appeal the most to consumers, certain design standards like symmetry must be followed in the final look of the product, and functions of each external piece, like a power button or volume button, must be placed in a way they are understood at a glance.

While a design is important, functionality for each piece of the design must be taken into account. The product’s design must reflect every single piece and component used and has to ensure that everything will work correctly when put together that way. However, it’s also possible to go in the opposite direction and over design a product to the point where it looks cluttered or messy. Hence, another rule is that simplicity is key to maintaining visual appeal for the end product.

PCB Design Tips:

- Use the entire surface area of the PCB. Note how densely you concentrate parts matrixes on the board. You will want to avoid parts so close together they require a hand solder or a pick-and-place machine relative to available resources.

- Make traces wide enough. The minimum trace width might not be wide enough if the required current is greater than a few hundred milliamps. Several factors play into this, like whether the trace is external versus internal-external layers can carry more current than an internal for the same thickness. Use a trace calculator to determine your trace width properly.

- Surface Mount Technology (SMT) vs. Through Holes. Not only does SMT have a nicer aesthetic, but larger components only come in SMT format.

- Errors in landing patterns. Prepare, print, and review a document of all connections. Most PCB software packages include libraries of electronic parts to ensure all components and pins align. However, it is easy to make mistakes on the landing pattern, especially if your Bill of Materials calls for components not found in the provided libraries. Double-checking this step will save time and money.

- Print 1:1 Scale. This is a simple, easy step to make sure all your components fit on your board.

- Capacitor placement and decoupling. Decoupling capacitors should be as close to the pin requiring clean, stable voltage as possible. Place your decoupling capacitor on the power supply rail to help serve this purpose.

- Optimize the layout of switching regulators. There are two types of electronic voltage regulators; linear regulators and switching regulators. Linear regulators are inexpensive, simple to the layout but can waste a lot of power. Switching regulators are more complex but much more efficient for applications requiring higher power and lower noise.

- Blind and buried vias. Avoid them if you can. A blind via connects an external layer to an internal layer, and a buried via connects two internal layers. No matter what, a via passes through all layers of the PC board to connect traces from one layer to the next. Both types of vias can result in the size of the PCB increasing as well as the cost. Each has limitations based on how layers stack on the board and should be avoided.

Conclusion

When a product is well designed, it can have a resounding impact on a consumer’s opinion of it, from their decision to pick it up or not, or how much they’re willing to recommend it to their peers. Design and visual appeal separate the profitable products from the rest, and when style and functionality come together, it becomes a guaranteed recipe for success.

Last Updated on February 3, 2021.