Additive manufacturing, more commonly known as 3D printing, is the process of building three-dimensional objects by uploading computer-aided design (CAD) files into a 3D printer. With a few clicks and commands, the 3D printer then extrudes the chosen material — usually thermoplastics, photopolymers, and metals — layer by layer, until a solid three-dimensional rendering of the object is completed.

The technology has come a long way since its inception in 1974 by British chemist David E.H. Jones, whose groundbreaking concept of using monomers to create solid objects has been developed over the years. And today, there is still plenty of room for exciting innovation.

In 2019, enterprise tech writer Louis Columbus outlined the different applications of 3D printing across a wide range of industries. Manufacturing is, of course, the broad sector that benefits the most. The health and medical sectors are among the industries under manufacturing that stand to gain with the further development of 3D printing, and between 2010 and 2016, the number of US hospitals with 3D printing capabilities rose by 3,200%. In the industry, there’s a lot of focus on prototyping, product development, quality control, and rapid-fire production of objects — but how exactly does this fall within the scope of medicine?

Let’s take a look at the major applications of 3D printing in healthcare and how it’s poised to continue transforming the industry:

3D printed medical tools

Given that manufacturing is one of the main objectives of the tech, it’s only natural to begin with medical devices built with 3D printers. Let’s look at a recent example: Last October, surgical tool manufacturer Shukla Medical partnered with Markforged, a major provider of metal and carbon fiber 3D printers, to create surgical instrument prototypes. In doing so, the company reportedly saved hundreds of thousands of dollars, providing a perfect illustration of how 3D printing tech aims to offer cost-cutting solutions to industries that need it the most, particularly healthcare.

But how was this done? Shukla Medical is known for providing orthopedic instruments used for implant removals and their subsequent replacement, such as in the hip, knee, or spine. Using tools built from the Markforged 3D printer, the manufacturing company was able to create carbon fiber and metal prototypes of various surgical tools. After practicing on these prototypes, surgeons reportedly spent less time on each procedure without compromising the safety of the patients. On the business side of medicine, shorter operating hours is equivalent to saving money.

Other tools that can be made from 3D printers include forceps, clamps, and scalpels, all of which are used regularly in hospitals. 3D printing also offers the advantage of precision in manufacturing smaller surgical instruments, which are quite literally life-saving.

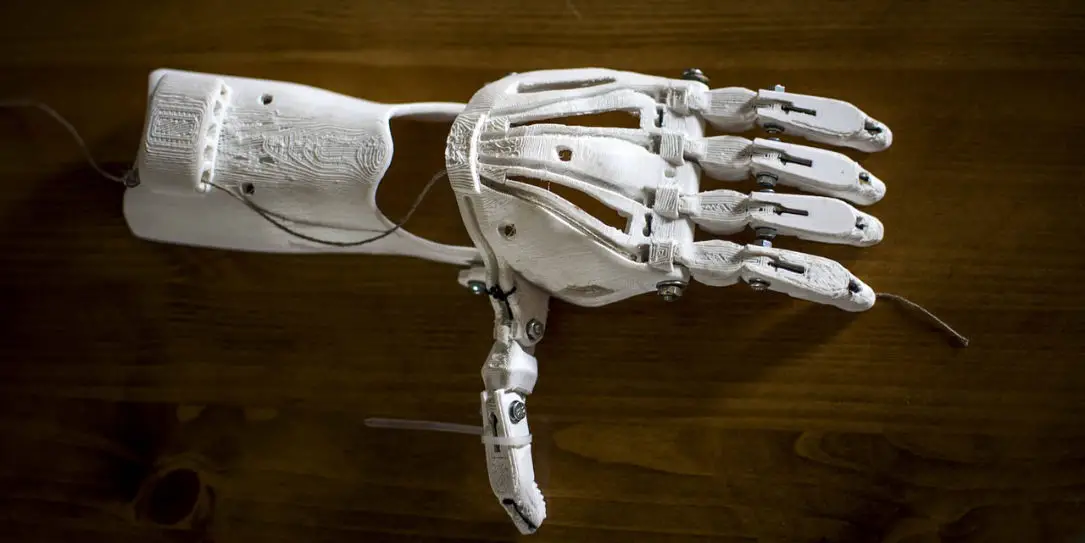

Prosthetics

Traditionally, the process of making prosthetics — which entails impression-making or casting, fabrication, and final fitting — is lengthy. Amputees have to wait anywhere from 3 weeks to 6 months before receiving their custom-fit prosthetics. But the rise of 3D printing and additive manufacturing means that this is no longer the case, as the technology significantly cuts down the time needed to build prosthetics for each person in need. Case in point, Fictiv notes how fully customized 3D printed parts can be available in as little as 24 hours, with the technology ensuring high-quality precision through both machine specs and dedicated manual inspections. This makes it easier for approximately 30 million people who are in need of prosthetic or orthotic devices, according to global reports.

Moreover, 3D printed prosthetics offer the same functionality as traditional ones, but at a much affordable price. Tech Crunch reports that the minimum asking price for traditional prosthetics is $5,000 and can go as high as $50,000. At that amount, you can already buy your own 3D printer, some of which are on sale for around $200, and print your own custom-made limb. The cheaper costs not only make prosthesis more accessible to the millions of people who need it, but it also benefits children who eventually outgrow their artificial limbs and will need new ones.

A notable startup in this space is Body Labs, which was recently acquired by Amazon. The software offers 3D scanning of limbs to create a more natural-looking and better-fitting replacement.

Bioprinting

Bioprinting is the process of manufacturing biological materials, like cells and tissues that mimic the ones in our bodies. There are many reasons why this is considered a groundbreaking technique in the field of medicine. First and foremost, it reduces — and might someday eliminate — the need to harvest organs and tissues from living organisms, like humans and animals. This doesn’t just help with the ethics side of medical research, as it is also critical in conducting clinical trials, specifically ones that involve drug testing and life-threatening procedures. With the availability of lifelike tissues and organoids, as they’re technically termed, researchers can then test treatment and administer drugs without harming other organisms in the process. This means that they can continue to develop treatment and medicine in hopes of eradicating illness.

On top of that, bioprinting also makes artificial organs a possibility, having the potential to transform thousands of lives. For example, the US has a long waiting list of patients in need of a liver transplant alone — at 17,000 patients hoping to be the subject of one of the lucky 6,000 liver transplants performed each year. This is why bioprinting companies like Organovo have taken on the challenge. While fully functional artificial organs are not quite where they need to be yet, Organovo has made some success in developing therapeutic liver tissues that can help people suffering from liver disease. Another example is an advanced brain organoid created by researchers from the Wake Forest Institute. This 3D printed brain is currently being used as an anatomical model for stroke research, which could help in the prevention of the silent killer.

Lastly, building artificial organs can also serve as practice for surgeons in preparation for complicated procedures. This ensures a more smooth-sailing training process and minimizes trauma for actual patients.

Reconstruction and joint replacement surgeries

Last but not least is replacement and reconstruction surgeries, and for this, we turn to the story of Cameron Underwood. A victim of a self-inflicted gunshot wound, Underwood was in dire need of a face transplant just last year. He was admitted to the NYU Langone Medical Center, where he was attended to by plastic surgeon and face transplant specialist Dr. Eduardo Rodriguez.

Rodriguez used 3D technology, both imaging, and printing, in order to create a model of Underwood’s face and replace its missing parts. He then noted how the tech allowed him and his team to work with speed and precision, which were critical in the patient’s case. And at the end of a grueling 25-hour surgery, Rodriguez and his team were successful. Today, the number of cases exhibiting the need to reconstruct or replace critical body parts is growing, and 3D printing technology is becoming a reliable solution.

All in all, reconstruction and replacement are two of the major applications of 3D printing in healthcare, with bioprinting, prosthetics, and manufacturing of surgical tools additional uses. The technology is finding new and exciting methods for treatment and cures while making critical care a more efficient process. And aside from cutting costs, what’s common among these applications is how 3D printing can help in saving lives, as it is very accessible to all.

What do you think of 3D printing and the healthcare industry? Let us know in the comments below or on Twitter, or Facebook. You can also comment on our MeWe page by joining the MeWe social network.

Last Updated on February 3, 2021.