3D printing has risen from obscurity to become a mainstream technology in the past decade. Yet, unless you have actually had hands-on experience with the equipment used to achieve it, you might not understand how it actually works.

To remedy this, here is a beginner’s guide to 3D printing that should clear up any questions you have and perhaps convince you to experiment with additive manufacturing yourself.

The basic principles

In the simplest terms, 3D printing works opposite to most traditional manufacturing techniques. Rather than starting with a large piece of material and gradually removing layers until you have fashioned it into the desired size and shape, you start with a blank printing bed and instead build up the desired structure by depositing material with a printing head, incrementally creating it layer by layer.

In terms of the materials that 3D printing works with, the most commonly used are thermoplastics, both affordable and easy to manipulate using the heated printing heads of compatible equipment. Of course, because the principles of 3D printing are straightforward and versatile, it is also possible to print with materials as diverse as metals, ceramics, and even concrete.

Furthermore, you do not even need to splash out on the hardware yourself to get a design turned into a 3D printed object. Online solutions like the 3DHubs printing service let you order components online and have them made and shipped to you in days.

The benefits

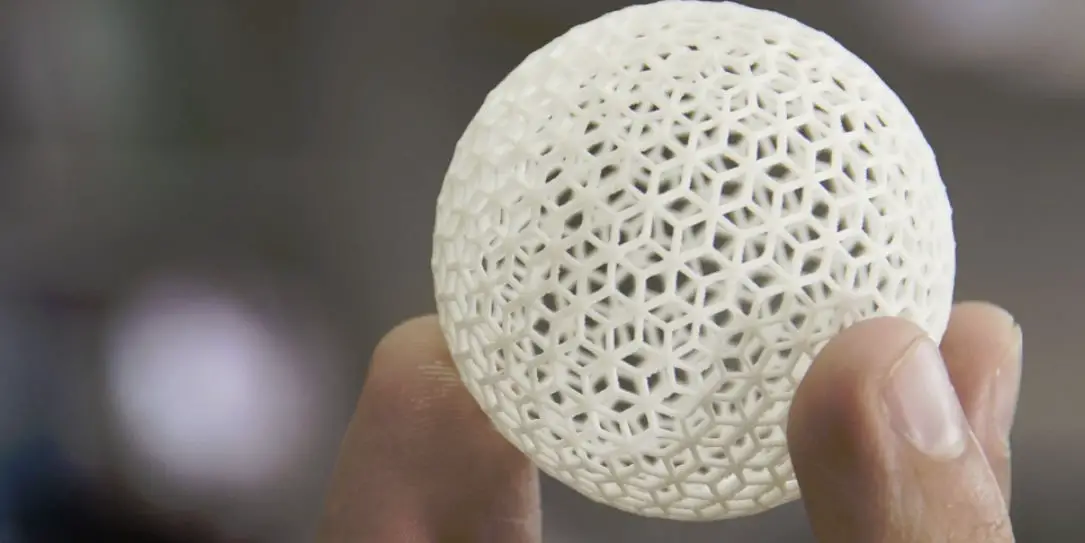

The biggest selling point of 3D printing is its ability to create objects and shapes which would be difficult or entirely impossible to produce using alternative approaches. If you can dream it up and create it in CAD software, the chances are that you can also print it out in the material of your choice.

The second benefit of note is that it creates far less waste than manufacturing techniques, which involve removing material. This is especially relevant in an age when the drive towards sustainability is greater than ever.

Finally, the fact that designs are so easy to share and print means that it offers individuals and organizations an amazing amount of flexibility. For example, rather than having to ship spare parts for cars out to dealerships when needed, 3D printing allows them to be produced locally, avoiding delivery delays and order errors.

The caveats

Although it is clearly appealing for many reasons, 3D printing is not perfect. In comparison with CNC machining, it can take a lot longer to make a part via 3D printing, and the levels of precision in the finished product will also be lower.

Furthermore, 3D printing tech is still in its relative infancy compared with more established approaches, meaning it is better suited to prototyping than to fully-fledged mass production where consistency and repeatability are key.

That said, 3D printing is not just for hobbyists but is proving instrumental in fuelling innovation in a range of industries, so it is well worth considering as an option today.

What do you think? Let us know in the comments below or on Twitter, or Facebook. You can also comment on our MeWe page by joining the MeWe social network.

Last Updated on August 16, 2021.